-

XimeX CFD simulation : quantifying the mixing efficiency – for twin screw and mixers

Process optimization by CFD numerical simulation

XimeX-TSE and XimeX-MXR are numerical simulation software coming from the XimeX portfolio. Both are dedicated to industrial processes simulation, with:

- XimeX-TSE focusing on corotating twin screw extruders

- XimeX-MXR simulating industrial mixers (batch, planetary, static…)

They are powerful 3D CFD software providing easy descriptions by making simulations of industrial twin screw extruders and mixers. Whatever the applications (as long as we consider fluid materials), whatever the equipments, XimeX-TSE and XimeX-MXR describe the behaviour of the material evolution according to the screw/mixer geometry and process conditions.

Available for all kind of applications : polymers, agrofood, pharma, construction materials, chemicals, energetical materials…

Process focused analysis

XimeX-MXR and XimeX-TSE are dedicated to process engineers. They focus on the material/process aspects only (numerical settings are predefined) to provide tools and results in line with the industrial environment

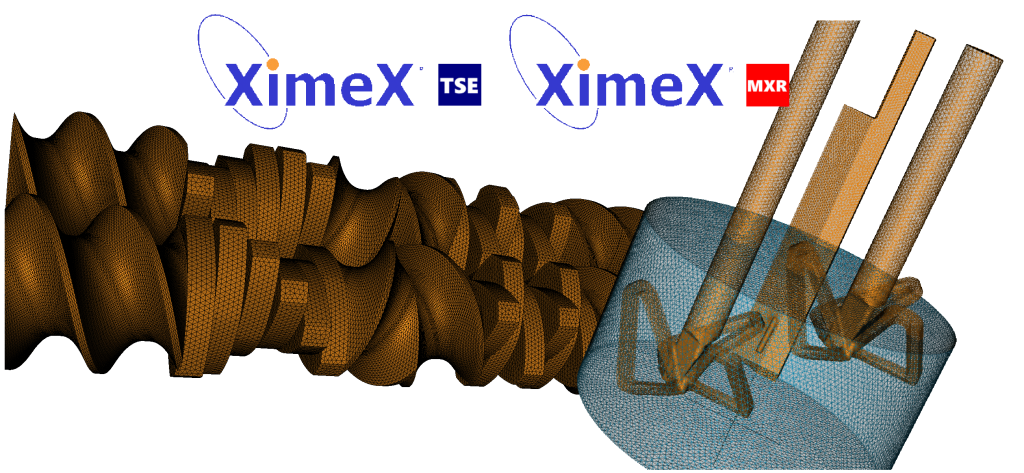

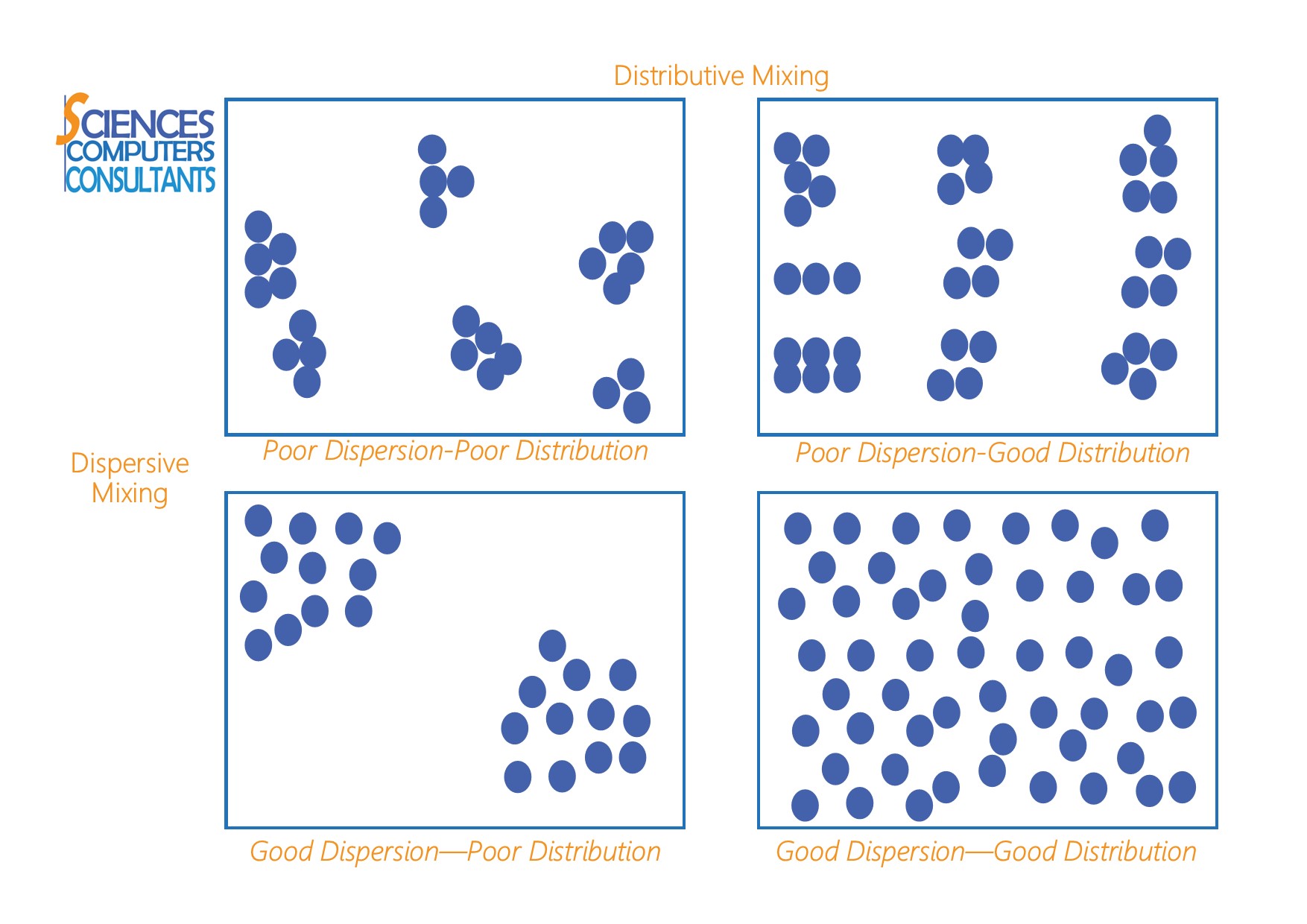

XimeX helps in quantifying the mixing capabilities of a given configuration.

Different tools helps in specific application, among:

- Identifying optimal functinoning point

- Optimizing geometry design (screw design, blades/rotors geometry…)

- Proposing scale up conditions

- Doing reverse engineering

- Increasing productivity

Two step computation

XimeX proposes a 2-step analysis for adapting the level of detail you can get from the simulation:

- a CFD computation layer showing the changes in material characteristics over time

- a Particle tracking layer highlighting the process mixing efficiency

XimeX-MXR : batch mixer application

Batch mixer : CFD analysis

XimeX-MXR proceeds with a two step analysis :

- a first CFD Computation: for getting the main information about the flow evolution

- a second computation based on a particle analysis

In the example shown on the right, the shear rate is computed and its evolution is displayed in function of time. This result is aimed at figuring out the zones of high shear (near the blades and rotors). And also identifying the potential dead zones of a mixer tank.

These results are especially useful for visualizing the changes over time during the mixing process. Analalyzing the shear rate distribution curve provides a quantified insight into the mixing capabilities of the process.

Particle tracking

In the second stage of computation, particles are used to track the fluid motion over time. Analyzing specific properties of the particles gives access to various phenomena description.

In this example, particles reflect the cumulated dissipated energy in order to observe the mixing efficiency.

Cumulated dissipated energy in the mixer is representative of the dispersive mixing effect (as an example, to break particles agglomerate).

Using this type of result makes the comparison between different mixer configurations (geometry or conditions) really easy and straightforward.

XimeX-MXR : internal mixer application

Adapting the process conditions

Internal mixers are very often used for material formulation and preparation, at a lab scale.

Larger scales are used for preparing the scale up to industrial equipments.

With XimeX-MXR, key data about process efficiency and material evolution are easily computed. In this case, we focus on shear (for the CFD computation and Cumulated Dissipated Energy for the particles computation). Many other results are available : temperature, viscosity, velocity, cumulated heating, stretch coefficient, cumumated strain..

XimeX-TSE : for twin screw comparison

For corotating twin screw extruder indeep analysis

Twin Screw Extruder (TSE) remain very widely used machines in the industry for their versatility and high mixing efficiency. Moreover, as a continous process, TSE is THE process for reaching high productivity levels.

With XimeX-TSE, configuration, testing and optimization of twin screw configuration is now at your fingertips.

Key thermo-mechanical data are computed and in depth analyzed using the CFD and particles computations.

Adapted software package

XimeX-TSE and XimeX-MXR are available as software or consulting. XimeX is developped from the Cimlib, by the CEMEF – Mines ParisTech.

Different type of licenses can be purchased. Contact SC-Consultants for more details.

For more details, contact

SCIENCES COMPUTERS CONSULTANTS

10 rue du plateau des glières

F-42000 Saint Etienne

France

https://www.scconsultants.com

scc@scconsultants.com